Happy lifestyles from our heart to yours.Techino Global

Weight Checker

PRODUCTS & SERVICES

Weight Checker

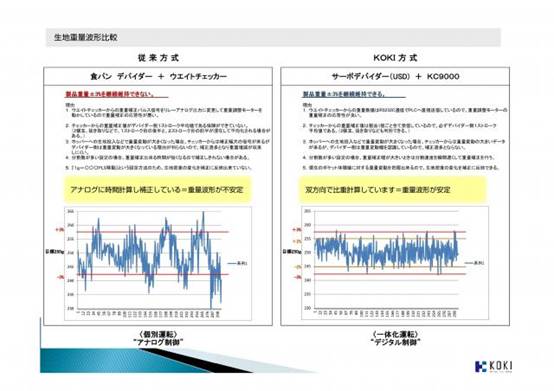

Accurate weighing of dough instantly feeds back data and records

◆It can realize bidirectional comparison and feedback of data with the integrated device of the divider.◆Realization of specific gravity calculation method.Calculate the specific gravity according to the state (...